Will New Waste Incinerator Technology Reduce Emissions?

Waste plays a prominent role in the emission of CO2. Housing Industry Leaders looks at how new technology by Siemens and Xetrov will help tackle these emissions for net-zero.

In the UK, the waste management sector consists of emissions from waste disposed of from landfill sites, waste incineration, and the treatment of wastewater.

Incinerators emit large quantities of CO2 with roughly one tonne of CO2 is produced for every tonne of waste incinerated, and around half of this comes from fossil sources such as plastics.

Yet, without incinerating this waste much of it would end up in landfill sites. So, what solutions are there in place to extract this waste without emitting harmful gases?

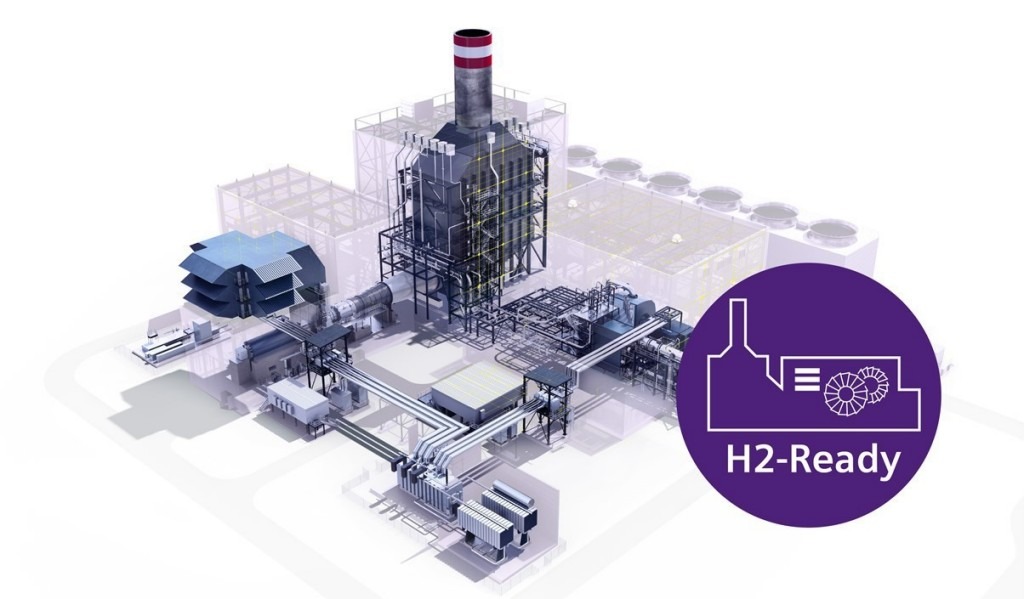

Siemens Digital Industries is teaming up with waste incinerator maker Xetrov Group to boost the production of its ground-breaking Clean6 Vortex.

Currently, waste management is the fifth most emitting sector of greenhouse gases in the UK.

2019 figures show waste management responsible for 4% of the UK’s CO2 emissions

The Clean6 Vortex aims to transform this by having a 98% conversion rate with only 2% residue, against the 80-90% efficiency rate of incinerators used in the industry.

The technology’s ability to process previously unrecyclable materials and its efficiency in using the exhaust heat generated by the Vortex to produce electricity, district heating and food production is ‘turning heads’ in the recycling and waste processing world.

Brian Holliday, Managing Director at Siemens Digital Industries UK told Housing Industry Leaders: “Siemens is delighted to have been selected by Xetrov for supplying end-to-end solutions for the ground-breaking incinerator, Clean6 Vortex.

The benefits of this conversion technology to the community and its potential contribution to the UK’s net-zero emissions targets are going to be huge.

“This technology is in sync with Siemens’ own goals of achieving a net-zero carbon footprint by 2030 across all our production facilities and buildings globally. We are fully geared and equipped to meet the specific requirements of Xetrov as it continues its mission of revolutionising waste processing and recycling.”

Siemens will supply the end-to-end solutions for producing the incinerators, including the G120 Inverter, the S7-1500 controller, the ET200 I/O for control cabinets, process instrumentation (flow and level sensors), control products, power supplies, HMI, IoT box, Scalence managed switches and some more products that are still under discussion.

This integrated approach provides diagnostic benefits, such as secure remote access and opens the door for IoT connection.

Over 11.6 million tonnes of waste was sent for incineration between 2019-20

The Clean6 Vortex

Siemens’ products will be used in all four components of the Clean6 Vortex machine, including the incinerator, crusher, boiler and potentially steam turbine.

Xetrov has created a bespoke modular solution suitable for the UK to the roll-out of decentralised waste-to-energy plants.

Each module consists of three core Clean6 Vortex advanced thermal treatment units and has a maximum waste processing capacity of 3 tonnes per hour (24,000 tonnes per annum).

Founder & CEO of Xetrov, Ashleigh Ruxton told Housing Industry Leaders: “We have been scouting for a partner that understands and shares our goals, Siemens brought to the table a slew of products that will go a long way in making our solution stronger and smarter.

Our advanced thermal conversion technology (Clean6 Vortex or Vortex) is not only 98% efficient on waste destruction but also requires less than half the waste compared to competing technologies to produce power. In all this, the role of the technology supplier is very critical.

“The digital technologies used are the future of machine development, deployment and are important for remote secure connectivity for future-proofing our innovative product. We have a strong environmental and social remit and want to contribute to the UK’s zero-landfill target and a reduction of CO2,”

Xetrov Group’s mission embraces the circular economy, carbon reduction, low-to-no emissions, decentralised power generation, and zero landfill. The Clean6 Vortex will have a very high 98% conversion rate with only 2% residue, against the 80-90% efficiency rate of incinerators used in the industry.

The Clean6 Vortex has exhaust emissions, which are significantly lower than required by the Industrial Emissions Directive (IED).

In addition, the technology does not produce any fly ash, as other incinerators normally do. Inert residues are typically 2% and are certainly below many of the alternative technologies.

The product is in sync with the UK Government’s target of having no more than 10% of waste going to landfill by 2035 against the current rate of 24%.